Printing on glass: technology and equipment

Not only decorators actively use image printing on glass:

In the automotive industry, for example, they are used to give the glass more functionality by applying special graphic elements in order to:

protection from the sun (darkened "visors" on the windshield);

enhancing anti-glare effects (transparent elements);

reinforcement;

markings, etc.

With individual glazing of yachts, the elements of printing on glass solve similar problems.

Glass has been used in architecture for a long time – it is one of the cheapest building materials. In order to avoid an excess of the same type and boring concrete-glass structures in cities, decorative details with applied images, color accents, made with the help of special equipment are included in building projects.

In the interior decoration of the premises there are also many details made of glass – partitions, doors, stair railings and even steps. Durable glass structures are decorated with color printing.

Furniture is an endless field of technology application. Cabinet doors, countertops, kitchen aprons… The pattern printed on glass is stylized as natural stone, marble; beautiful flower bouquets delight the eye, while ennobling the object; printing photos on glass – as a reminder of unforgettable milestones of life; printing paintings on glass, reproductions of famous artists, brings a special charm to the interior. The possibilities are unlimited.

Glass printing technologies: limited variety

There are two main types of printing on glass:

Direct (UV printing, silk-screen printing), for which UV printers are used. A high-resolution image is applied to the glass surface with special paints. Advantages of direct printing:

detail, clarity and brightness of the drawing;

durability;

burnout resistance;

moisture resistance;

you can decorate the relief surfaces.

Indirect (film). In this case, the image is applied to a transparent film, which is then glued to the glass with polymer glue. Advantages of the technology:

the film is firmly connected to the surface of the glass;

when the glass is destroyed, it does not allow the fragments to fly apart;

the image can be replaced if you are tired of it;

low cost.

Triplex printing is based on the film technology of printing on glass, that is, the image is applied to a special film, after which the finished drawing is placed between sheets of glass. The image is protected from two sides, maintaining a two-way view, providing a high level of security for a person.

UV printing technology: a technological breakthrough

The use of this technology became possible with the advent of special equipment on the market – large-format printing printers, which are controlled using special software. UV printing on glass allows you to apply the image directly to the surface without using stencils. UV decor looks luxurious due to the accurate transfer of color, details.

Special inks are used, which harden instantly under the light of ultraviolet lamps built into the printer. As soon as it hits the carrier, the UV paint freezes, forming a polymer film firmly connected to the glass. The picture appears right before your eyes, after the printer the product is ready for use. UV direct printing on glass made it possible to reduce the time required for drawing drawings.

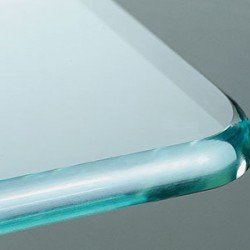

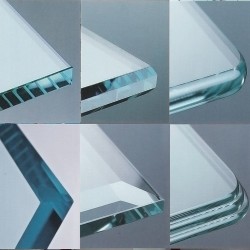

The printer for printing on glass creates a clear pattern. Since the glass surface is glossy and resistant to adhesion, it is pre-treated with a special compound. The edges of the canvas with the applied pattern are treated with a European edge (a straight or curved polished edge, or a polished edge of the canvas).

UV printing on glass has a number of advantages:

the paint allows you to create bright and resistant to mechanical influences drawings;

immediately after application, the product is ready for use;

the capabilities of the equipment allow you to apply drawings to any surface.

Silk screen printing on glass: fine work

Silkscreen printing is a direct digital printing on glass based on the use of pre—prepared mesh stencils. The essence of the technology lies in the fact that through special "grids" of paint, stage by stage, they are pressed onto the surface, then the pattern is baked.

Depending on the complexity of the drawing, in order to get a full-color print, various methods of applying a paint layer are used: they change the degree of tension of the stencil, use mesh printing plates of different types, select paints that differ in quality, change the method of drying the paint, and so on.

The screen printing stencil is a frame with a stretched nylon mesh. Depending on the desired effect, the mesh cells can be of different sizes, and the mesh threads can be of different thicknesses. It is made separately for each color and is processed with a photosensitive emulsion before work, followed by additional processing: dried, exposed, developed, washed.

moisture resistance,

UV resistance,

resistance to mechanical stress.

The paint after being applied to the glass undergoes heat treatment – within 2 to 5 minutes it is tempered at a temperature of 650 degrees.

3D printing: three-dimensional drawings of extraordinary beauty

3D printing on glass is a special technology that allows you to print a drawing on glass that has a three–dimensional character, with an expressive surface and a different texture. 3D printing is a rather complex process that takes place in several stages:

The surface is degreased, cleaned of dust, dried and treated with a solution (primer) to improve adhesion.

The outline of the image is created with white paint. In one pass, the printer applies one millimeter of contour. Depending on the desired elevation, the printer passes over the same area several times.

A colored layer is applied over the created contour. The difficulty lies in the need for an accurate color hit on an already existing white impression.

The finished image is processed with varnish.

Printing on film

This type of indirect printing on glass is still very popular. In this case, UF printing takes place on special films:

transparent with shock protection;

matte and glossy decorative films of the "oracle" type